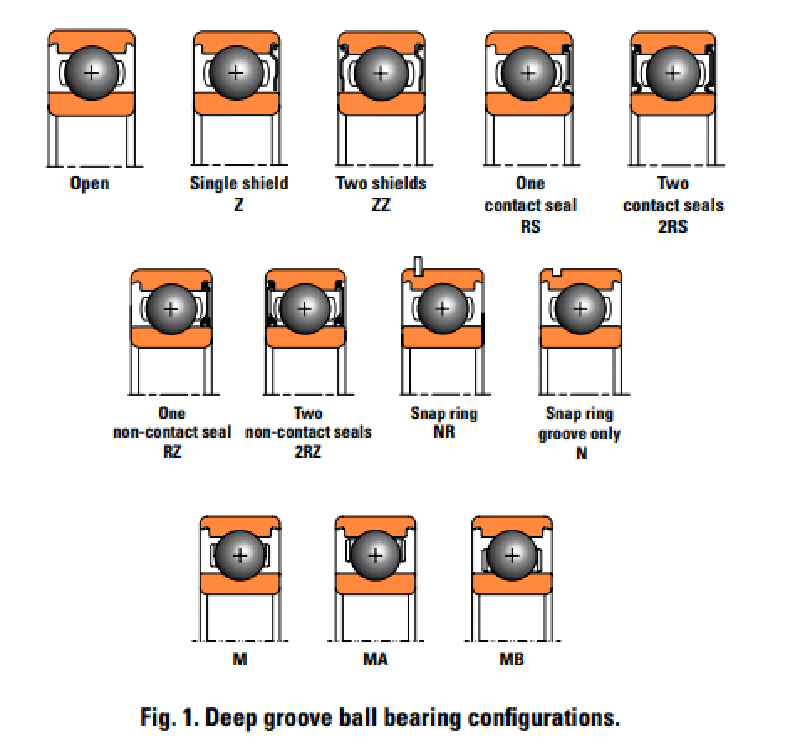

As one of the most versatile rolling bearing types, Timken deep groove ball bearings are widely used in industrial applications to support radial and axial loads under high speed conditions. They are available in a comprehensive range of sizes, materials and sealing configurations to suit different operating requirements.

The single-row deep groove design is the most common, providing low friction and high precision in high-speed applications from small bore sizes of 1mm up to over 50mm. Open, sealed and shielded variants help protect the bearing in contaminated environments. Double-row angular contact bearings can manage combined loads in medium sized applications from 25mm to 100mm bore diameters.

Where corrosion resistance is required, Timken offers stainless steel deep groove ball bearings marked with a “W” in the part code. The stainless steel material provides corrosion protection while maintaining similar performance to standard steel bearings. Popular sizes are between 1mm to 50mm bore.

For very high speed applications, ceramic hybrid bearings with steel rings and ceramic balls provide increased stiffness and lower friction. Their high dimensional stability suits precision applications. Usual sizes range from 15mm to 35mm bore.

For extreme temperatures, specialized coatings and bearing materials such as silicon nitride ceramic enable deep groove ball bearings to operate beyond the capability of standard steel. Dimensional fits are application specific.

Please let me know if the length of title and content now meets your requirements. I’m happy to make further adjustments.

Post time: Oct-18-2023